Assets and Subsea Materials

Thompsons of Prudhoe can provide assets for onshore decommissioning of offshore oil and gas installations as well other oil and gas equipment for both onshore and offshore use such as topsides, jackets and structures.

Onsite NORM Treatment Facility

This state-of-the-art Naturally Occurring Radioactive Material (NORM) facility, located at our site in the Port of Blyth, provides an onshore turnkey solution and high quality decommissioning programme to our customers based in oil and gas facilities across and in the North Sea.

At our NORM facility in Blyth, offshore oil and gas materials don’t need to be sent off for cleaning as they can be done onsite at our onshore facility. This geographical and industrial strategy removes the need for materials to be transported to other facilities across the country, which both saves transportation & decommissioning costs for customers and reduces our carbon emission levels.

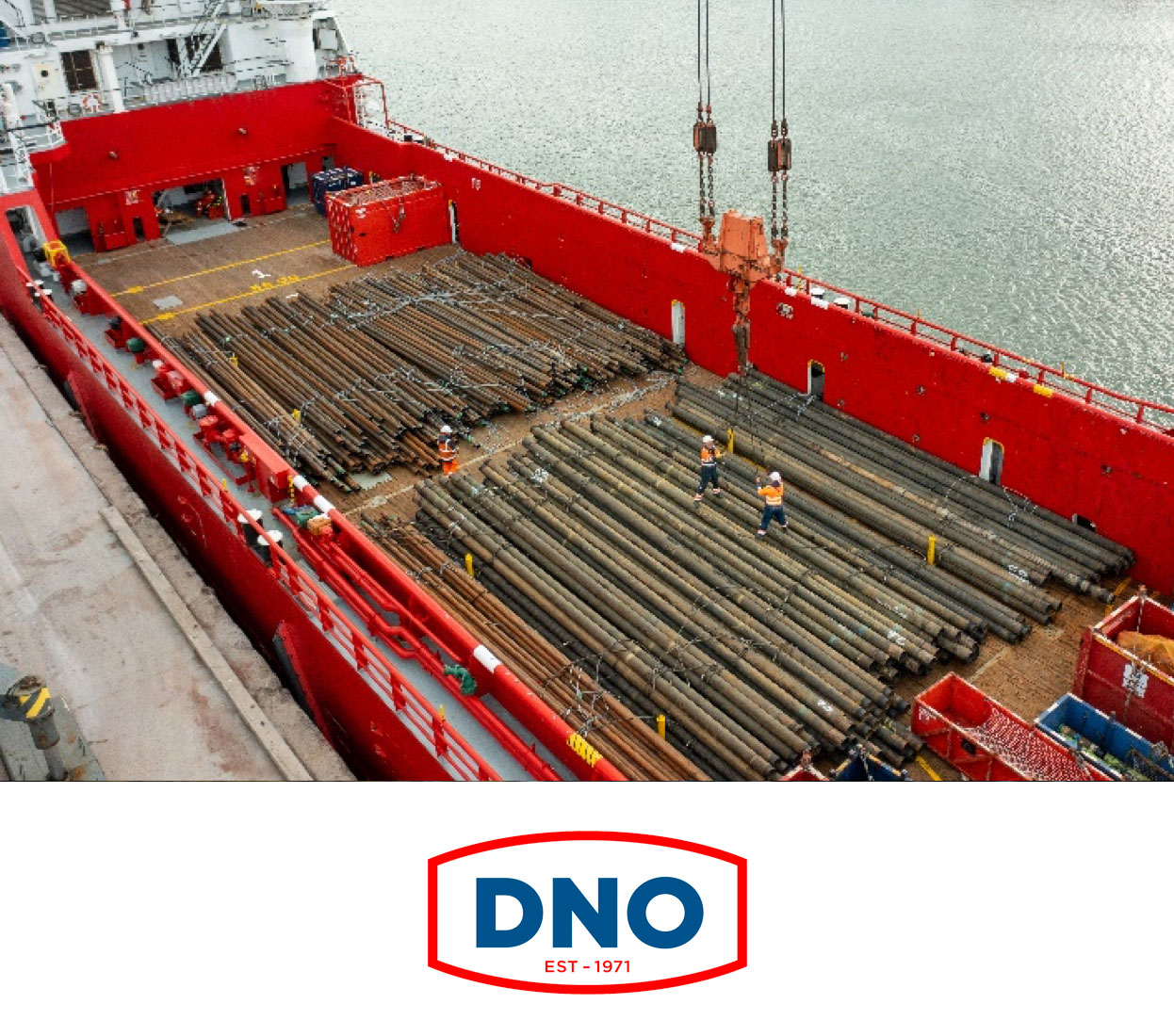

The Port of Blyth specialises in project cargo handling and movement for the offshore energy sector. Thompsons of Prudhoe have full engineering and operational support for landing and moving equipment/pieces including lift/movement plans There is port cranage of up to 100 tonne lift capacity readily available on site for work on the quayside or the decommissioning site. There is also heavy lift cranage of up to 500-tonne lift capacity – available on site from heavy-lift partners.

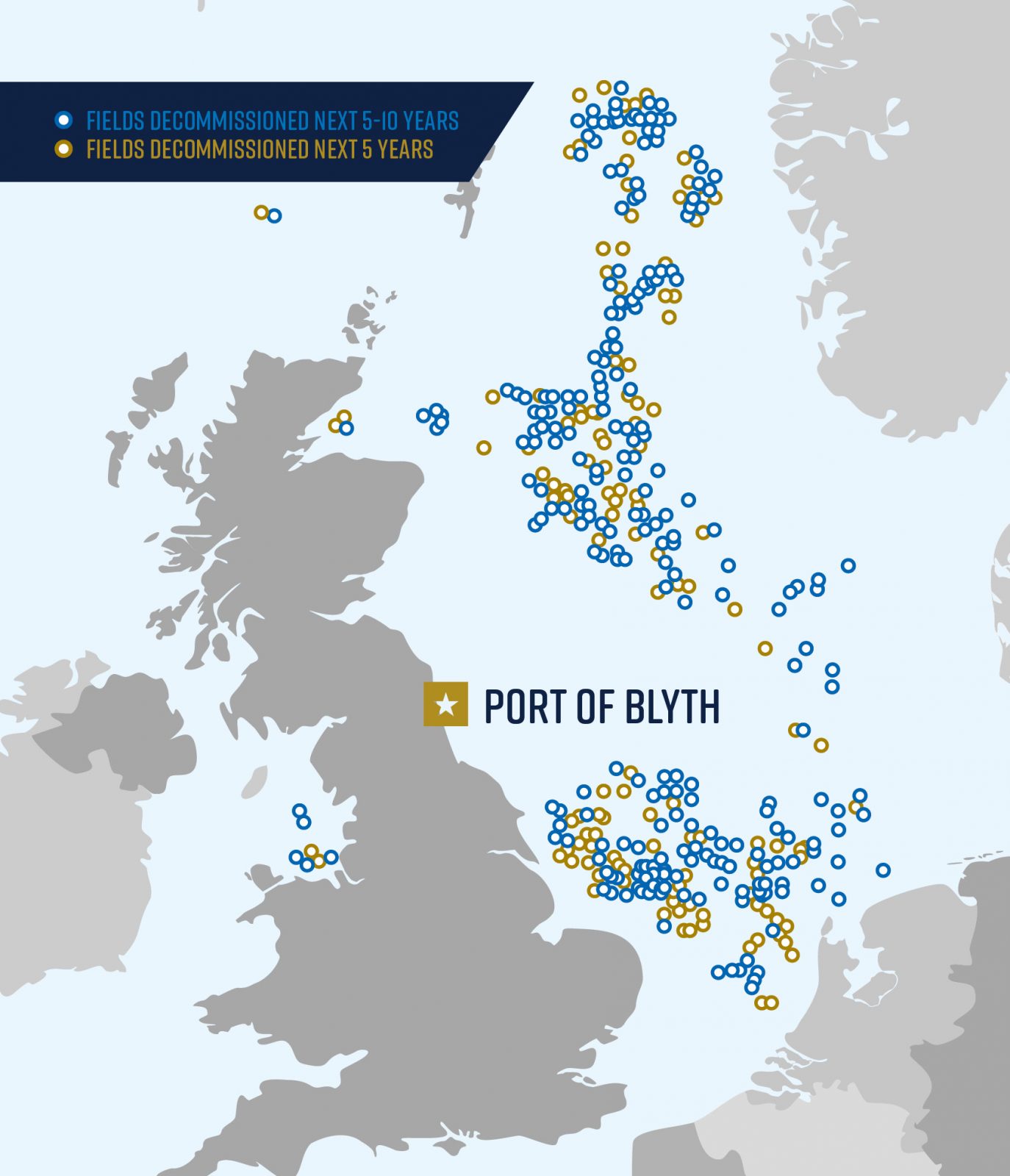

Thanks to our partnership with the Port of Blyth, Thompsons of Prudhoe are proud to be strategically placed on the east coast of the UK, midway between Aberdeen and Great Yarmouth. This industrial strategy means that we are well placed for decommissioning assets from the Northern, Central and Southern North Sea sectors, allowing us to maximise the number of decommissioning programmes we can carry out.

There are also substantial, uncongested road links to the Port – with Newcastle International Airport only a short 20 minute drive away.